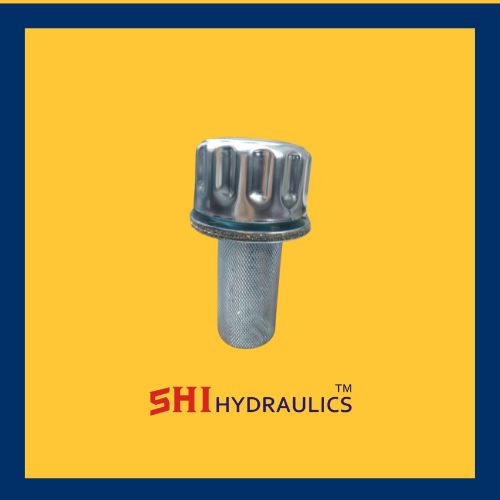

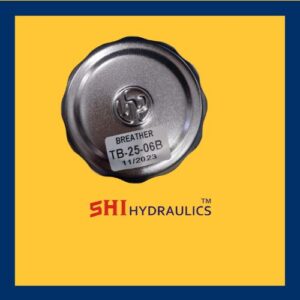

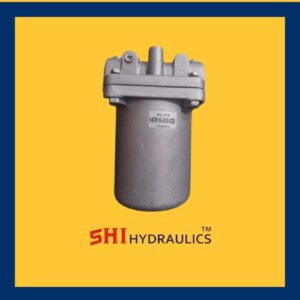

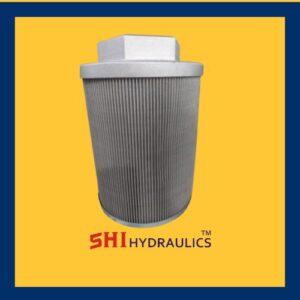

Breather

Key Features of a Breather

- Filtration:

- Equipped with a filter medium, such as synthetic fibers or metal mesh, to capture dust, debris, and other particulates.

- Helps protect internal components from damage caused by contamination.

- Ventilation:

- Allows free flow of air in and out of the system to equalize pressure during operation or temperature changes.

- Compact Design:

- Typically small and lightweight, making it easy to integrate into various systems.

- Durable Construction:

- Made from materials such as aluminum, stainless steel, or reinforced plastic to withstand harsh operating conditions.

- Moisture Control:

- Advanced models may include desiccant materials to absorb moisture from incoming air, preventing condensation inside the system.

Types of Breathers

- Standard Breathers:

- Basic models with a simple filter for general applications.

- Desiccant Breathers:

- Include moisture-absorbing desiccant material, ideal for environments with high humidity.

- Pressure Relief Breathers:

- Designed to maintain specific pressure levels by opening or closing a valve when the pressure exceeds preset limits.

- Hydraulic Breathers:

- Used in hydraulic reservoirs to allow the system to “breathe” while keeping out contaminants.

- Engine Breathers:

- Common in automotive and industrial engines, they manage crankcase ventilation to prevent pressure buildup and oil leaks.

- Gearbox Breathers:

- Prevent contamination and manage pressure changes in gearboxes, ensuring smooth operation and reduced wear.

Applications of Breathers

- Hydraulic Systems:

- Protect hydraulic reservoirs from contamination while allowing pressure equalization.

- Gearboxes and Transmissions:

- Prevent overpressurization and protect internal components from dirt and moisture.

- Engines:

- Manage crankcase ventilation and maintain optimal pressure levels.

- Storage Tanks:

- Allow air exchange while preventing contaminants from entering tanks containing fuel, water, or chemicals.

- Industrial Equipment:

- Used in compressors, pumps, and other machinery to maintain clean and dry air environments.

- Wind Turbines:

- Protect critical components from environmental contamination while managing airflow.

Benefits of Using a Breather

- Enhanced System Performance:

- Maintains clean airflow, reducing wear and tear on internal components.

- Contamination Prevention:

- Keeps dirt, dust, and moisture out of the system, improving reliability.

- Pressure Regulation:

- Prevents vacuum or overpressurization that can lead to leaks or component failure.

- Extended Equipment Life:

- Reduces the risk of damage caused by contaminants or improper pressure levels.

- Cost Savings:

- Lowers maintenance costs and minimizes downtime by protecting sensitive components.

Design and Materials

Breathers are made from high-quality materials to ensure durability and resistance to harsh environments:

- Housing: Typically constructed from stainless steel, aluminum, or plastic for strength and corrosion resistance.

- Filter Medium: Made from synthetic fibers, wire mesh, or desiccant materials for effective filtration and moisture control.

- Seals and Gaskets: Use elastomeric materials like rubber or silicone to ensure airtight connections.

Maintenance and Replacement

To ensure optimal performance, breathers require regular maintenance and timely replacement:

- Inspection:

- Check for signs of clogging, damage, or contamination during routine system maintenance.

- Cleaning:

- Clean or replace the filter medium as needed to maintain airflow and filtration efficiency.

- Replacement:

- Replace breathers according to manufacturer recommendations or when performance diminishes.

- Environmental Considerations:

- Choose breathers with desiccants or advanced filtration for high-humidity or dusty environments.

₹800.00

Related Products

Related products

Customer Reviews

★★★★★ 5/5

“A review from a customer who benefited from your product. Reviews can be a highly effective way of establishing credibility and increasing your company's reputation.”

Customer Name

★★★★★ 5/5

“A review from a customer who benefited from your product. Reviews can be a highly effective way of establishing credibility and increasing your company's reputation.”

Customer Name