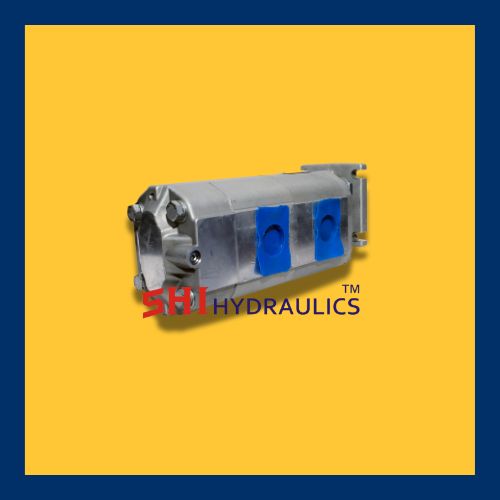

HDD Gear Pump

HDD Gear Pump Overview

(Hydraulic Driven Displacement) are widely used in industrial applications, primarily in hydraulic systems, due to their durability, efficiency, and ability to handle high-pressure environments. These pumps are a type of positive displacement pump, and their design ensures the consistent flow of fluid regardless of changes in pressure. This makes them particularly suitable for systems where precise control and reliability are crucial.

Basic Design and Operation

HDD consist of two main gears: the driving gear and the driven gear. These gears mesh with each other inside a housing and work together to move hydraulic fluid through the system. The driving gear is typically powered by an external motor, which turns the gears and forces the fluid into the discharge side of the pump.

As the gears rotate, fluid enters the pump chamber through an inlet port. The fluid is trapped between the teeth of the gears and the housing, and as the gears continue to rotate, the trapped fluid is carried around the gear teeth and pushed out the outlet port. This process is continuous, resulting in a steady flow of fluid.

One of the main advantages of gear pumps is their ability to maintain a constant flow rate, which is a key requirement in many hydraulic systems. The flow is determined by the size of the gears and the speed at which they rotate. By adjusting the speed of the motor or changing the gear size, the flow rate can be modified to meet the needs of the application.

Applications of Pumps

used in a wide variety of applications, including but not limited to:

Hydraulic Systems: These pumps are used in machinery such as forklifts, excavators, and cranes, where they provide hydraulic fluid to power various parts of the system.

Automotive: In the automotive industry, HDD gear pump are used in power steering systems, transmission fluid pumps, and oil pumps.

Oil and Gas: The pumps are used for fluid transfer in drilling rigs, offshore platforms, and refineries.

Industrial Manufacturing: HDD can be found in various manufacturing plants where precise fluid transfer is necessary, such as in plastic injection molding or lubrication systems.

Advantages

High Efficiency: Gear pumps are known for their high efficiency, particularly in terms of energy conversion. The meshing of gears minimizes energy loss, which makes them more energy-efficient compared to other types of pumps.

Durability: Gear pumps are built to last. They are resistant to wear and tear, even under heavy-duty use. The metal construction of the gears and housing allows the pump to withstand high-pressure conditions without failure.

Compact Design: Despite their power, gear pumps are relatively small and compact, making them ideal for applications with limited space. This makes them a good choice for use in machinery or equipment where size constraints are a consideration.

Smooth Flow: Gear pumps provide a steady and continuous flow of fluid, which ensures stable operation in hydraulic systems. This reduces the potential for erratic movements or system failures.

Versatility: These pumps are versatile in terms of the fluids they can handle. They can work with a variety of liquids, including oils, water, and other industrial fluids. Depending on the materials used, they can even handle viscous fluids or those with particulates.

Limitations and Challenges

Despite their advantages, pumps also have certain limitations:

Maintenance and Care

Regular maintenance is crucial for ensuring the

Related Products

Related products

Customer Reviews

“A review from a customer who benefited from your product. Reviews can be a highly effective way of establishing credibility and increasing your company's reputation.”

Customer Name

“A review from a customer who benefited from your product. Reviews can be a highly effective way of establishing credibility and increasing your company's reputation.”

Customer Name