Hydraulic Fittings

Hydraulic fittings are crucial components in hydraulic systems, connecting hoses, pipes, and tubes to direct and control the flow of hydraulic fluid under high pressure. Designed to ensure leak-proof connections and reliable performance, these fittings play a vital role in maintaining system efficiency, safety, and durability. Used across industries such as construction, agriculture, aerospace, and manufacturing, hydraulic fittings come in various materials, types, and configurations to suit specific applications.

Functions of Hydraulic Fittings

The primary functions of hydraulic fittings are as follows:

- Connection:

- Provide secure and reliable links between hoses, tubes, and other hydraulic components.

- Fluid Containment:

- Prevent leaks by creating a tight seal, ensuring optimal system efficiency.

- Pressure Resistance:

- Withstand high pressures without compromising the integrity of the connection.

- Flexibility:

- Allow easy assembly, disassembly, and maintenance of hydraulic systems.

- Adaptation:

- Facilitate connections between components of different sizes, materials, or thread types.

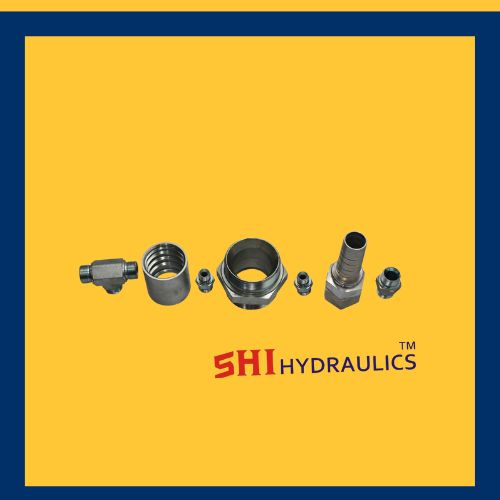

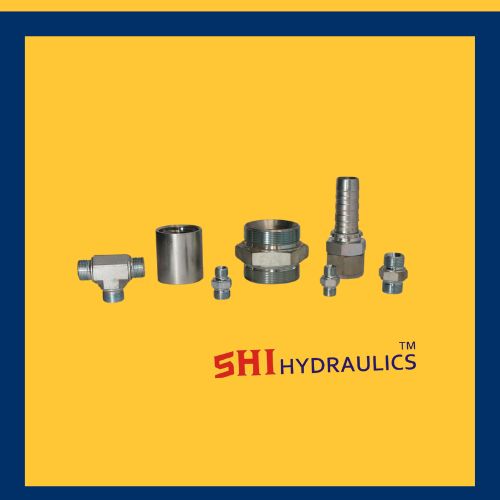

Types of Hydraulic Fittings

Hydraulic fittings are categorized based on design, connection method, and sealing mechanism. Common types include:

1. Threaded Fittings:

- Use threads to create a secure connection. Common standards include NPT (National Pipe Thread), BSP (British Standard Pipe), and metric threads.

- Ideal for low to medium-pressure applications.

2. Flare Fittings:

- Feature a conical seat that matches the flare of the tubing, creating a seal when tightened.

- Commonly used in high-pressure systems, such as automotive and aerospace hydraulics.

3. Compression Fittings:

- Employ a ferrule or sleeve that compresses against the tubing to form a seal.

- Suitable for both low and high-pressure applications, offering easy assembly.

4. O-Ring Face Seal (ORFS) Fittings:

- Incorporate an O-ring in the face of the fitting for a leak-proof connection.

- Provide excellent resistance to vibrations and high pressures.

5. JIC Fittings (Joint Industry Council):

- Use a 37-degree flare angle for sealing, ensuring compatibility with a wide range of hydraulic systems.

6. Push-to-Connect Fittings:

- Enable quick and tool-free connections by pushing the hose or tube into the fitting.

- Suitable for low-pressure systems or pneumatic applications.

7. Swivel Fittings:

- Allow rotational movement between connected components, reducing stress and wear on hoses.

- Common in applications with frequent motion or vibration.

Materials Used in Hydraulic Fittings

Hydraulic fittings are manufactured from various materials to match system requirements and fluid compatibility:

- Steel:

- High strength and durability make steel fittings ideal for heavy-duty and high-pressure systems.

- Often treated with coatings like zinc to resist corrosion.

- Stainless Steel:

- Provides excellent resistance to corrosion, making it suitable for harsh environments and chemical exposure.

- Brass:

- Offers good corrosion resistance and is commonly used in low to medium-pressure applications.

- Aluminum:

- Lightweight and corrosion-resistant, suitable for applications requiring weight reduction.

- Plastic:

- Used in low-pressure systems, offering cost-effectiveness and corrosion resistance.

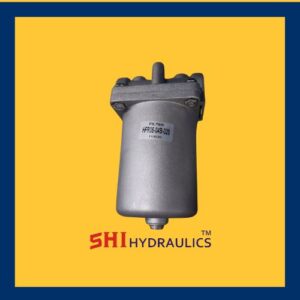

Applications of Hydraulic Fittings

Hydraulic fittings are integral to numerous industries and applications, including:

- Construction:

- Connect hoses and components in heavy machinery like excavators, loaders, and bulldozers.

- Agriculture:

- Ensure efficient hydraulic operation in tractors, harvesters, and irrigation systems.

- Automotive:

- Used in hydraulic braking systems, power steering, and transmission systems.

- Aerospace:

- Provide reliable connections in hydraulic systems of aircraft for landing gear and flight control.

- Industrial Manufacturing:

- Facilitate the operation of hydraulic presses, injection molding machines, and conveyor systems.

- Oil and Gas:

- Handle high-pressure and high-temperature fluids in drilling and refining operations.

₹500.00

Related Products

Related products

Customer Reviews

“A review from a customer who benefited from your product. Reviews can be a highly effective way of establishing credibility and increasing your company's reputation.”

Customer Name

“A review from a customer who benefited from your product. Reviews can be a highly effective way of establishing credibility and increasing your company's reputation.”

Customer Name