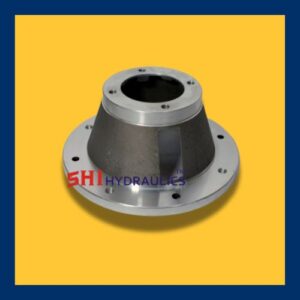

Breather

Breather: Essential Component for Pressure and Contaminant Control

A breather is a critical device designed to equalize pressure and allow airflow in enclosed systems while preventing the ingress of contaminants such as dirt, moisture, and debris. Used in a wide array of applications, breathers play a vital role in maintaining the integrity and performance of mechanical and hydraulic systems, ensuring longevity and efficiency.

Breathers are commonly found in hydraulic systems, gearboxes, engines, tanks, and other equipment that require controlled ventilation to manage pressure fluctuations caused by temperature changes or fluid movement.

What is a Breather?

A breather is a venting device equipped with a filtration element that allows air to pass into and out of an enclosed system while blocking contaminants. It is designed to maintain an optimal operating environment by preventing internal vacuum or pressure buildup and ensuring that only clean air enters the system.

Key Features of a Breather

- Filtration:

- Equipped with a filter medium, such as synthetic fibers or metal mesh, to capture dust, debris, and other particulates.

- Helps protect internal components from damage caused by contamination.

- Ventilation:

- Allows free flow of air in and out of the system to equalize pressure during operation or temperature changes.

- Compact Design:

- Typically small and lightweight, making it easy to integrate into various systems.

- Durable Construction:

- Made from materials such as aluminum, stainless steel, or reinforced plastic to withstand harsh operating conditions.

- Moisture Control:

- Advanced models may include desiccant materials to absorb moisture from incoming air, preventing condensation inside the system.

Types of Breathers

- Standard Breathers:

- Basic models with a simple filter for general applications.

- Desiccant Breathers:

- Include moisture-absorbing desiccant material, ideal for environments with high humidity.

- Pressure Relief Breathers:

- Designed to maintain specific pressure levels by opening or closing a valve when the pressure exceeds preset limits.

- Hydraulic Breathers:

- Used in hydraulic reservoirs to allow the system to “breathe” while keeping out contaminants.

- Engine Breathers:

- Common in automotive and industrial engines, they manage crankcase ventilation to prevent pressure buildup and oil leaks.

- Gearbox Breathers:

- Prevent contamination and manage pressure changes in gearboxes, ensuring smooth operation and reduced wear.

Applications of Breathers

- Hydraulic Systems:

- Protect hydraulic reservoirs from contamination while allowing pressure equalization.

- Gearboxes and Transmissions:

- Prevent overpressurization and protect internal components from dirt and moisture.

- Engines:

- Manage crankcase ventilation and maintain optimal pressure levels.

- Storage Tanks:

- Allow air exchange while preventing contaminants from entering tanks containing fuel, water, or chemicals.

- Industrial Equipment:

- Used in compressors, pumps, and other machinery to maintain clean and dry air environments.

- Wind Turbines:

- Protect critical components from environmental contamination while managing airflow.

Benefits of Using a Breather

- Enhanced System Performance:

- Maintains clean airflow, reducing wear and tear on internal components.

- Contamination Prevention:

- Keeps dirt, dust, and moisture out of the system, improving reliability.

- Pressure Regulation:

- Prevents vacuum or overpressurization that can lead to leaks or component failure.

- Extended Equipment Life:

- Reduces the risk of damage caused by contaminants or improper pressure levels.

- Cost Savings:

- Lowers maintenance costs and minimizes downtime by protecting sensitive components.

Design and Materials

Breathers are made from high-quality materials to ensure durability and resistance to harsh environments:

- Housing: Typically constructed from stainless steel, aluminum, or plastic for strength and corrosion resistance.

- Filter Medium: Made from synthetic fibers, wire mesh, or desiccant materials for effective filtration and moisture control.

- Seals and Gaskets: Use elastomeric materials like rubber or silicone to ensure airtight connections.

₹580.00

Related Products

Related products

Customer Reviews

“A review from a customer who benefited from your product. Reviews can be a highly effective way of establishing credibility and increasing your company's reputation.”

Customer Name

“A review from a customer who benefited from your product. Reviews can be a highly effective way of establishing credibility and increasing your company's reputation.”

Customer Name