Key Components of a Filter Element

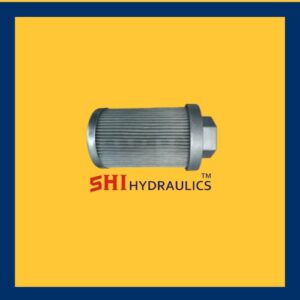

- Filter Media:

- The core material that captures contaminants.

- Common materials include paper, synthetic fibers, wire mesh, or pleated membranes.

- Media type determines the filtration efficiency and compatibility with different fluids or gases.

- Support Structure:

- Provides rigidity and durability to the filter element.

- Includes perforated metal cores, wire mesh, or plastic frames to support the filter media.

- End Caps:

- Securely seal the ends of the filter element.

- Made from metal, plastic, or composite materials, ensuring compatibility with the operating environment.

- Seal or Gasket:

- Prevents fluid bypass, ensuring that all fluid passes through the filter media.

- Commonly made from rubber, silicone, or elastomeric materials.

Types of Filter Elements

Filter elements are categorized based on their application and filtration mechanism:

- Hydraulic Filter Elements:

- Used in hydraulic systems to remove dirt, metal shavings, and other contaminants.

- Protect components like pumps, valves, and cylinders from wear and tear.

- Air Filter Elements:

- Designed to filter particulates from the air in engines, HVAC systems, or industrial applications.

- Protect machinery and improve air quality.

- Fuel Filter Elements:

- Clean fuel before it reaches the engine or equipment, preventing clogging and ensuring efficient combustion.

- Oil Filter Elements:

- Remove impurities from lubricating oils, ensuring smooth operation and reducing wear.

- Water Filter Elements:

- Eliminate sediments, chlorine, and impurities from water for drinking, industrial, or agricultural use.

- Gas Filter Elements:

- Used in gas pipelines or systems to remove particulates or moisture.

Functions and Benefits

- Contaminant Removal:

- Traps unwanted particles, extending the lifespan of machinery and systems.

- Improved Efficiency:

- Ensures clean fluid or air flow, optimizing performance.

- Reduced Maintenance Costs:

- Prevents damage to system components, minimizing repair or replacement expenses.

- Enhanced Reliability:

- Maintains consistent system performance, reducing the risk of breakdowns.

- Environmental Protection:

- Helps in reducing emissions and waste, supporting sustainability efforts.

Materials Used in Filter Elements

- Cellulose:

- Cost-effective and commonly used for basic filtration needs.

- Synthetic Fibers:

- Offer high filtration efficiency and durability.

- Metal Mesh:

- Suitable for high-pressure or high-temperature applications.

- Ceramics:

- Used for fine filtration in extreme environments.

- Activated Carbon:

- Adsorbs odors, chemicals, and impurities, often used in air or water filtration.

Applications of Filter Elements

- Automotive:

- Fuel, oil, and air filters for cars, trucks, and heavy machinery.

- Industrial:

- Filtration systems in manufacturing, power plants, and chemical processing.

- Hydraulic Systems:

- Critical in construction, agriculture, and industrial equipment.

- Food and Beverage:

- Ensures purity in water, beverages, and edible oils.

- Aerospace:

- Protects aircraft engines and hydraulic systems.

Maintenance and Replacement

Regular maintenance and timely replacement of filter elements are crucial to ensure optimal system performance. Key practices include:

- Monitoring Performance:

- Check for pressure drops or reduced efficiency, indicating a clogged filter.

- Scheduled Replacement:

- Replace filter elements based on manufacturer recommendations or operating conditions.

- Inspection:

- Regularly inspect filters for damage or wear.

- Proper Disposal:

- Dispose of used filter elements responsibly to minimize environmental impact.

Innovations in Filter Element Design

- Nanotechnology:

- Nanofiber media enhances filtration efficiency for ultrafine particles.

- Reusable Filters:

- Washable and reusable elements reduce waste and lifecycle costs.

- Smart Filters:

- Embedded sensors monitor filter condition and notify users of maintenance needs.

- Eco-Friendly Materials:

- Biodegradable or recyclable filter media reduce environmental impact.