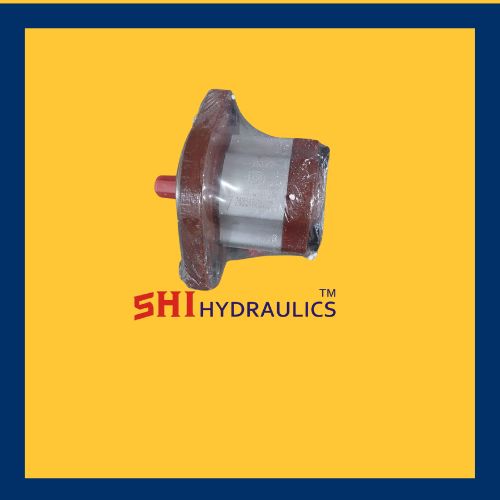

Gear Pumps: A Reliable Solution for Fluid Transfer

A gear pump is a type of positive displacement pump that uses the intermeshing of gears to transfer fluids. Known for their efficiency, reliability, and simplicity, gear pumps are widely used in industrial, automotive, and agricultural applications. They are especially suited for handling viscous fluids and delivering consistent flow rates at varying pressures.

Design and Components of a Gear Pump

Gear pumps are compact in design and consist of essential components that work together to ensure smooth and efficient operation:

- Gears:

- The pump typically features two gears: a driving gear connected to the motor and a driven gear. These gears mesh together to create the pumping action.

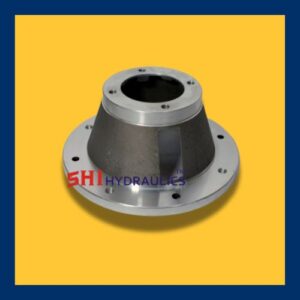

- Housing:

- Encloses the gears and maintains alignment. It is usually made from durable materials like cast iron, stainless steel, or aluminum, depending on the application.

- Inlet and Outlet Ports:

- Allow fluid to enter and exit the pump. The size and positioning of these ports influence flow rate and efficiency.

- Bearings and Seals:

- Support the rotation of the gears and prevent leakage, ensuring long-lasting operation.

- Relief Valve (Optional):

- Some gear pumps include a built-in relief valve to protect the system from overpressure conditions.

Working Principle

The operation of a gear pump is based on the positive displacement principle, where the rotation of gears creates a consistent flow of fluid. Here’s how it works:

- Fluid Entry:

- As the gears rotate, the spaces between the gear teeth increase on the suction side, creating a vacuum that draws fluid into the pump.

- Fluid Transport:

- The fluid is carried around the perimeter of the gears in the spaces between the teeth and the pump housing.

- Fluid Discharge:

- On the discharge side, the spaces between the gear teeth decrease as the gears mesh together, forcing the fluid out through the outlet port.

- Non-Reversibility:

- The tight meshing of the gears prevents backflow, ensuring a consistent and reliable discharge.

Types of Gear Pumps

Gear pumps come in two main types, each suited for specific applications:

- External Gear Pumps:

- Feature two external gears with teeth that mesh externally.

- Commonly used for high-pressure applications due to their robust construction.

- Internal Gear Pumps:

- Comprise an internal gear and an external gear, with the smaller external gear positioned inside the larger internal gear.

- Ideal for low-pressure applications and handling viscous fluids like oils and syrups.

Applications of Gear Pumps

Gear pumps are versatile and used in a variety of industries for fluid transfer and processing:

- Automotive:

- Serve as oil pumps, fuel pumps, and lubrication pumps in engines and transmissions.

- Chemical Processing:

- Handle corrosive and viscous chemicals in industrial systems.

- Food and Beverage:

- Transfer syrups, chocolate, and other high-viscosity ingredients with precision.

- Oil and Gas:

- Used in crude oil transfer, lubricating systems, and fuel dispensing.

- Hydraulics:

- Power hydraulic systems in machinery, such as loaders and excavators.

- Pharmaceuticals:

- Ensure accurate transfer of medicinal fluids under sterile conditions.

Advantages of Gear Pumps

Gear pumps offer numerous benefits that make them a preferred choice for many applications:

- Consistent Flow:

- Provide a steady, pulse-free flow that is independent of pressure variations.

- High Efficiency:

- Handle viscous fluids efficiently, making them suitable for heavy-duty applications.

- Compact and Durable:

- Feature a simple design with minimal moving parts, ensuring long service life and easy maintenance.

- Wide Range of Materials:

- Available in various materials, allowing compatibility with diverse fluids and operating environments.

- Self-Priming Capability:

- Can operate efficiently even in systems with an interrupted fluid supply.

- Versatility:

- Operate effectively at a wide range of pressures and temperatures.

Limitations of Gear Pumps

Despite their advantages, gear pumps have some limitations:

- Limited to Clean Fluids:

- Cannot handle abrasive or solid-laden fluids, as these can damage the gears.

- Noise Levels:

- Can generate noise at high speeds or pressures, requiring additional damping in some applications.

- Flow Variation with Wear:

- Over time, wear can increase internal clearances, slightly reducing flow efficiency.

- Lower Efficiency with Low Viscosity Fluids:

- May experience leakage or reduced performance with very thin fluids.

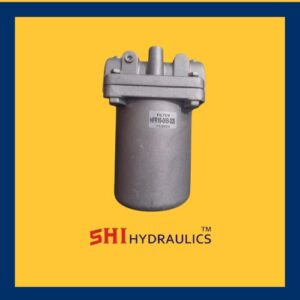

Maintenance and Best Practices

Proper maintenance is essential to ensure the efficient and reliable operation of gear pumps:

- Regular Inspection:

- Check for wear on gears, seals, and bearings to prevent leaks and efficiency loss.

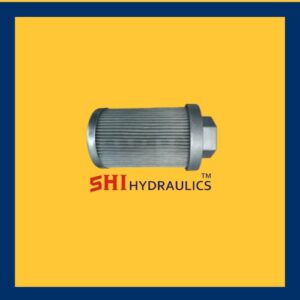

- Clean Fluids:

- Use filters or strainers to ensure only clean fluids pass through the pump.

- Monitor Operating Conditions:

- Avoid exceeding the pump’s pressure, temperature, and speed limits.

- Lubrication:

- Ensure adequate lubrication to minimize friction and wear.

- Replace Worn Parts:

- Address worn components promptly to prevent further damage and maintain performance.

Conclusion

Gear pumps are reliable, efficient, and versatile devices for fluid transfer and processing. Their ability to handle viscous fluids, maintain consistent flow, and operate in demanding conditions makes them invaluable in a wide range of industries. By selecting the appropriate type, maintaining the pump properly, and adhering to best practices, users can maximize the performance and lifespan of gear pumps, ensuring smooth and efficient operations.