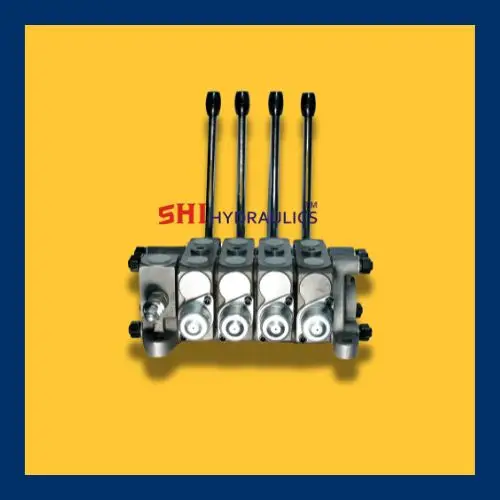

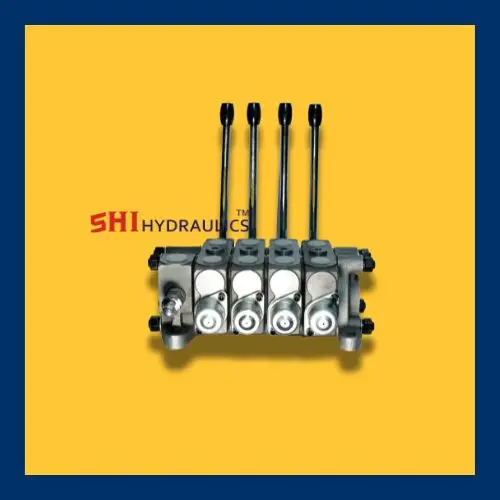

Mobile Control Valve

Monoblock Valve: A Comprehensive Overview

A Monoblock valve is a type of hydraulic valve that is designed as a single, compact unit. It plays a crucial role in controlling the flow,

Design and Structure of a Monoblock Valve

The primary characteristic of a Monoblock valve is its monoblock construction, where multiple valve functions

Monoblock valves typically

- Valve Body: The main housing that contains the valve’s internal components and channels. It is usually machined from a single piece of metal.

- Control Spools or Ball Mechanisms: These components control the flow direction and the opening

- Ports: The inlet and outlet ports that allow hydraulic fluid to enter and exit the valve. These ports are typically designed for high-pressure environments.

- Spring or Actuator Mechanism: Some block valves are spring-loaded, while others use solenoids or hydraulic actuators to control the valve’s movement and function.

- Seals and O-rings: These ensure that there are no leaks between the internal components, maintaining the integrity of the hydraulic fluid system.

Working Principle of a Monoblock Valve

- Flow Control: The valve’s internal mechanism, such as a spool or ball,

- Pressure Relief: Many monoblock valves include integrated pressure relief features.

- Direction Control: Monoblock valves can also control the direction of fluid flow. For example, a directional control valve in a monoblock

Types of Monoblock Valves

Monoblock valves come in various types, each designed for specific tasks within a hydraulic system. The most common types include:

- Directional Control Valves:

- These valves control the direction of the hydraulic fluid. They are used to change the flow direction,

- Flow Control Valves:

- Flow control valves regulate the flow rate of the hydraulic fluid in a system. conditions.

- Pressure Relief Valves:

- These valves are designed to maintain a preset maximum pressure in the hydraulic system. When the system’s pressure exceeds the set limit,

- Check Valves:

- Check valves allow fluid to flow in one direction only,

- Combination Valves:

- Some monoblock valves combine multiple valve functions into a single unit, such as a directional control valve with built-in pressure relief and flow control.

Advantages of Monoblock Valves

- Compact Design:

- One of the primary advantages of Monoblock valves is their compact design. Since all components are integrated into a single unit,

- Ease of Installation:

- The single-unit design of Monoblock valves simplifies installation.

- Cost-Effectiveness:

- Monoblock valves are generally more cost-effective than traditional valves that require multiple parts.

- Reduced Leak Points:

- With fewer parts and integrated construction,

- Improved Performance:

- The integration of multiple valve functions into a single unit reduces the number of components that could potentially fail,

Applications of Monoblock Valves

Monoblock valves are used in a wide range of applications across various industries, including:

- Construction Machinery:

- Monoblock valves are used in construction equipment like excavators, loaders, and backhoes to control the movement of hydraulic cylinders and motors.

- Agricultural Equipment:

- In agriculture, Monoblock valves control the operation of hydraulic systems in tractors, combine harvesters, and other farm machinery.

- Industrial Automation:

- These valves are widely used in industrial machines and production lines for controlling fluid flow to actuators, which is essential in automation processes.

- Mobile Equipment:

- Monoblock valves are commonly found in mobile machinery like cranes, forklifts, and material handling systems, where they manage the hydraulic flow for various operations.

- Automotive Systems:

- Monoblock valves are used in automotive applications, such as power steering systems and lifting mechanisms in heavy-duty vehicles.

Conclusion

Monoblock valves are essential components in hydraulic systems, offering a compact, cost-effective, and reliable solution for controlling fluid flow, pressure, and direction. Their integrated design minimizes installation time

Related Products

Related products

Customer Reviews

“A review from a customer who benefited from your product. Reviews can be a highly effective way of establishing credibility and increasing your company's reputation.”

Customer Name

“A review from a customer who benefited from your product. Reviews can be a highly effective way of establishing credibility and increasing your company's reputation.”

Customer Name