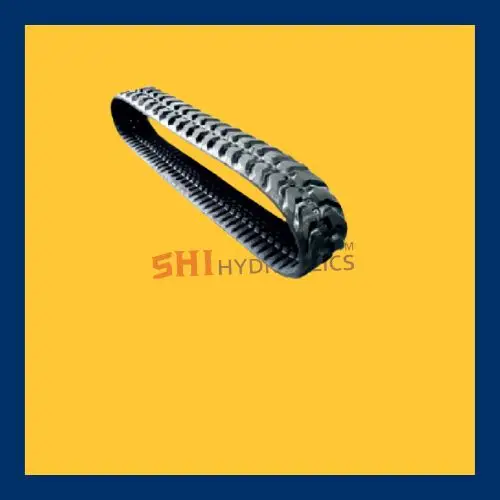

Rubber Tracks

Rubber Tracks

- Durable Construction

- Rubber tracks are manufactured using high-quality rubber compounds reinforced with steel or synthetic fibers, ensuring strength and resilience under heavy loads.

- Advanced Tread Design

- The treads on rubber tracks are designed to provide optimal grip on various terrains, including mud, snow, sand, and rocky surfaces.

- Flexibility

- Rubber tracks are flexible, allowing machinery to maneuver more effectively in tight or uneven spaces.

- Shock Absorption

- Rubber’s inherent elasticity reduces vibrations and absorbs shocks, enhancing operator comfort and minimizing wear on machinery.

- Reduced Noise

- Unlike steel tracks, rubber tracks operate with minimal noise, making them ideal for urban and residential areas.

Benefits of Using Rubber Tracks

- Improved Traction and Stability

- Rubber tracks offer exceptional grip on a variety of surfaces, reducing the risk of slippage and improving stability, even in challenging conditions.

- Minimized Ground Damage

- The wide surface area and softer material of rubber tracks distribute weight evenly, preventing damage to sensitive terrains like lawns, farmland, or pavements.

- Enhanced Versatility

- Compatible with a wide range of machinery, rubber tracks are suitable for applications in construction, agriculture, forestry, and more.

- Cost-Effectiveness

- Rubber tracks reduce fuel consumption by providing efficient movement and decreasing wear on the undercarriage of the equipment.

- Operator Comfort

- The shock-absorbing nature of rubber tracks ensures smoother operation, reducing operator fatigue during extended use.

- Environmentally Friendly

- Reduced ground disturbance and quieter operation make rubber tracks a sustainable choice for environmentally sensitive projects.

Types of Rubber Tracks

- Conventional Rubber Tracks

- Standard rubber tracks with simple treads for general-purpose applications.

- Non-Marking Rubber Tracks

- Designed for indoor use, these tracks prevent floor damage and are commonly used in warehouses and factories.

- Terrain-Specific Rubber Tracks

- Tracks with specialized tread patterns for specific terrains, such as deep lug tracks for mud or snow.

- Continuous Rubber Tracks

- Seamless tracks that provide greater durability and strength, often used in high-performance machinery.

- Interchangeable Rubber Tracks

- Modular designs allow for easy replacement and adaptability to different machinery.

Materials Used in Rubber Tracks

- Natural and Synthetic Rubber

- A combination of natural and synthetic rubber provides flexibility, durability, and resistance to wear.

- Steel Reinforcement

- Steel cords embedded within the rubber enhance structural integrity and tensile strength.

- Kevlar or Aramid Fibers

- Advanced fiber reinforcements improve resistance to cuts, punctures, and abrasion.

- Polymer Compounds

- Enhance track performance in extreme temperatures and provide resistance to UV exposure and chemicals.

Applications of Rubber Tracks

- Construction Equipment

- Used in excavators, skid-steer loaders, and mini-dozers for improved traction on construction sites.

- Agriculture

- Tractor tracks ensure minimal soil compaction and effective operation in muddy or uneven fields.

- Landscaping

- Ideal for machinery working on lawns or gardens to prevent ground damage.

- Forestry

- Rubber tracks enable machinery to navigate dense forests without harming the ecosystem.

- Military and Defense

- Light armored vehicles and transport equipment use rubber tracks for stealth and versatility.

- Snow Removal and Ski Resorts

- Snow groomers and other equipment rely on rubber tracks for effective movement on icy surfaces.

Maintenance and Longevity of Rubber Tracks

- Regular Cleaning

- Remove debris such as rocks and mud to prevent wear and tear.

- Proper Tensioning

- Ensure tracks are tensioned correctly to avoid slipping or excessive strain.

- Inspection for Damage

- Look for cracks, tears, or signs of wear to address issues promptly.

- Storage

- Store tracks in a cool, dry environment away from direct sunlight and chemicals to prolong their lifespan.

- Correct Usage

- Operate machinery within recommended weight limits and avoid sharp turns to minimize stress on the tracks.

Innovations in Rubber Track Technology

- Eco-Friendly Tracks

- Tracks made from recyclable materials for reduced environmental impact.

- Enhanced Tread Patterns

- Optimized designs for better grip and fuel efficiency.

- Smart Monitoring Systems

- Integrated sensors to monitor wear and alert operators when replacements are needed.

- Lightweight Designs

- Advanced materials reduce weight without compromising strength, improving overall efficiency.

Conclusion

Rubber tracks have revolutionized the way modern machinery operates by providing a balance of durability, versatility, and environmental care. Their ability to navigate diverse terrains while protecting the underlying surface makes them invaluable in industries ranging from construction to agriculture. With ongoing advancements in materials and design, rubber tracks continue to set new standards for performance, reliability, and sustainability.

₹20,000.00

Related Products

Related products

Customer Reviews

“A review from a customer who benefited from your product. Reviews can be a highly effective way of establishing credibility and increasing your company's reputation.”

Customer Name

“A review from a customer who benefited from your product. Reviews can be a highly effective way of establishing credibility and increasing your company's reputation.”

Customer Name