Understanding Hydraulic Motors: 5 Types and Uses

Hydraulic motors are essential components in a variety of industrial applications, providing efficient power flow through hydraulic fluid. The ability to convert hydroelectric energy into mechanical energy makes it indispensable in many industries, from construction to construction. In this blog we will explore different types of hydraulic motors, their working principles and applications.

What is a hydraulic motor?

A hydraulic motor is a device that converts hydraulic pressure into rotation. It works by pumping hydraulic fluid into the motor to create compressive pressure. This movement can then be used to drive or manipulate devices.

Basic business principles

The basic operation of a hydraulic motor involves several basic components:

Hydraulic fluid: An active fluid that transfers energy.

Pump: Supplies compressed water to the motor.

Motor Housing: Contains motor components.

Components: These may include gears, pistons, or vanes depending on the type of motor.

The flow of water inside the motor creates a pressure that keeps the components moving, causing them to rotate. This cycle can be used to turn a wheel or to move a conveyor belt.

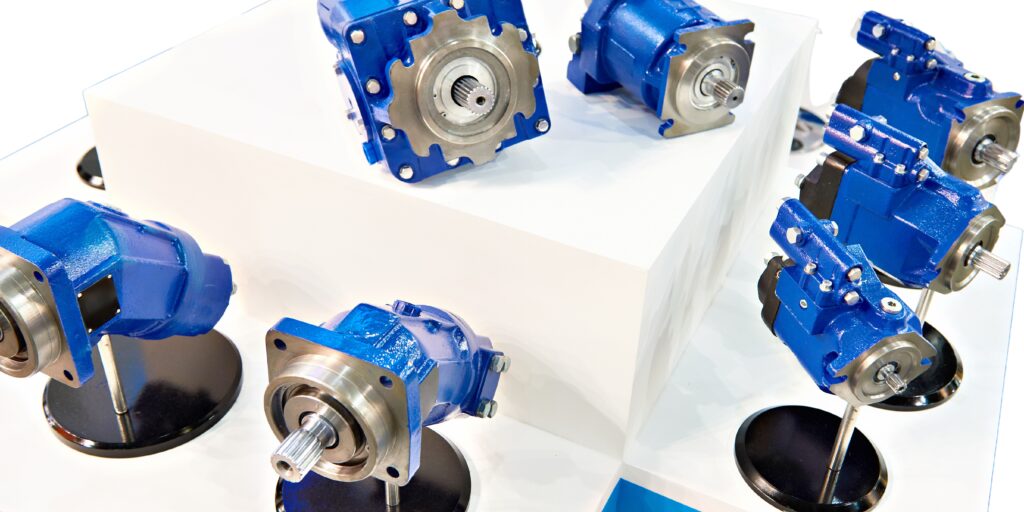

Hydraulic Motors

There are different types of hydraulic motors, and each one is designed for a specific application and operating conditions. There are some very common varieties

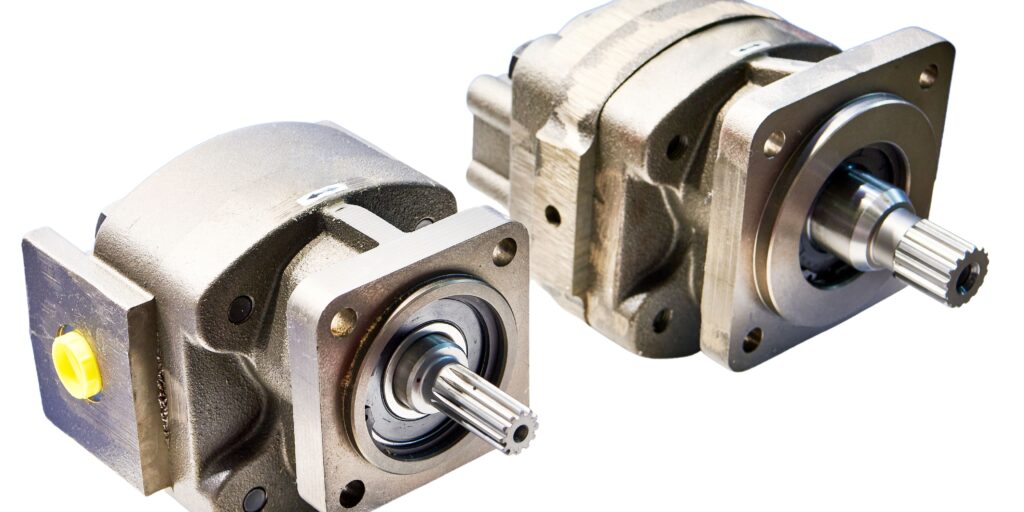

- Gear mechanisms

Description: Gear motors use gears to convert fluid pressure into rotation. It can be an external ignition motor or an internal ignition motor.

External gear motors: Have two gears (one connected and one driven) connected. Hydraulic fluid enters the space between the gears, allowing them to rotate.

Internal gear motors: Refers to an internal gear that rotates around an external gear. In general, this design allows for more torque at lower speeds.

Application: Gear motors are commonly used in agricultural machinery, utilities, and hydraulic systems where moderate speed and high torque are required

- Panel devices

Description: Vane motors use a rotor with sliding vanes that are pushed out by centrifugal force as the rotor rotates. The steam enters the motor and pushes against the vanes, causing the rotor to spin.

Applications: These devices are suitable for applications requiring efficiency and variable speed, such as in conveyor systems and woodworking machinery

- Piston machines

Description: Piston motors use cylinders with reciprocating pistons. Steam is pumped into these cylinders, pushing the pistons against the crankshaft, causing them to rotate.

Radial Piston Motors: The pistons are arranged radially around a central crankshaft.

Axial piston motors: The pistons are parallel to the axis of the motor and are driven by hydraulic fluid.

Applications: Piston motors are very efficient and are commonly used in high power applications such as excavators, cranes and various industrial machines.

Applications: Piston motors are very efficient and are commonly used in high power applications such as excavators, cranes and various industrial machines.

- Swashplate devices

Description: This device uses a swashplate mechanism that converts the linear motion of the piston into rotary motion. Adjustments can be made to the face of the swashplate to change the range and speed of the motor.

Application: Swashplate devices are used in applications requiring precise control of speed and torque, such as mobile equipment and high-performance machinery

- Screw machines

Description: Screw motors work on the principle of screw mechanics, where a single screw drives the rotation of the output shaft. The water vapor energizes the screw, converting linear motion into rotary motion.

Applications: These devices are typically used in applications requiring compact assembly and high efficiency, such as robotics and aerospace.

Benefits of Hydraulic Motors

Increased power and weight: Hydraulic motors can deliver high power while maintaining a minimum weight, making them ideal for mobile applications

Variable speed and power: Many water machines allow adjustment of speed and power, allowing flexibility.

Durability and durability: Hydraulic devices are designed to withstand harsh operating conditions, making them suitable for harsh environments.

Performance efficiency: The nature of hydraulic systems provides greater efficiency compared to mechanical systems, reducing resource consumption

Compact design: Many hydraulic devices can be designed to take up less space than equivalent electric devices, which is important in applications where space is limited

damage to hydraulic motors

Complexity: Hydraulics can be complicated and must be maintained to prevent leaks and damage.

Price: While hydraulic motors can be cost-effective in terms of performance, the initial investment and maintenance can be higher than an electric option

Environmental: Water sludge can be hazardous to the environment if it leaks, so it is important to handle and dispose of it with care.

Hydraulic Motors

Because of their versatility and efficiency, hydraulic motors are used in a wide range of applications. Here are some of the most commonly used

- Construction materials

Hydraulic motors are an integral part of heavy machinery such as excavators, bulldozers and cranes. They provide the power needed to efficiently lift, move and move heavy loads. - Agriculture

Hydraulic motors in agricultural machinery drive equipment such as tractors, harvesters and tillers, increasing efficiency and efficiency in agricultural operations - Construction work

In manufacturing, hydraulic motors power conveyor systems, robotic arms and CNC machines, which contribute to automation and accuracy in production. - Space issues

Flight systems use hydraulics to control landing gear, impact, and other critical features to ensure safe and reliable flight performance - The car

In automotive applications, hydraulic motors are used in systems such as power steering, braking systems and automatic transmissions to provide improved performance and controllability - Marine work

Hydraulic motors drive various types of equipment onboard ships, such as winches, steering systems and propulsion systems, and demonstrate their importance in marine applications - Renewable energy

Hydroelectric devices are used in renewable energy systems, such as waves and wave energy converters, where they help convert absorbed energy into usable electricity.

Conclusion

Hydraulic motors are essential components in many industries, providing reliable and efficient power. With a variety of adaptations designed for specific applications, it offers flexibility and efficiency in challenging environments. Understanding the types of hydraulic motors and their applications can help businesses become more efficient and improve efficiency. As technology continues to evolve, the role of a hydraulic motor is sure to expand, opening the door to even more new applications in the future. Whether in architecture, agriculture or construction, hydraulics remain the cornerstone of modern engineering solutions.